History and Advancement of Terry Weaving

The material of “terry”, received its

name from the way the terry towels were manufactured in earlier decades. The towels are typically

manufactured by compiling loops and then pulling them out to form a soft

textile. In history, these loops were pulled out by hand, providing these

towels an accurate name. The name “terry” comes from the French word “tirer”,

meaning to pull. Traditionally, terry cloths are either made simply by hand or

by means of two yarn system weaving (Powell & Yilmaz, 2005).

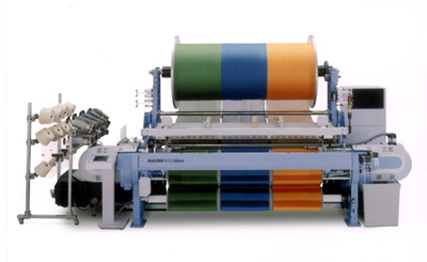

As technology becomes more advanced, the production of terry fabrics begins to increase in complexity and processing times are longer and more sensitive. To create a durable terry textile in large quantities, it is required that a weaving machine be present for assistance. The weaving machine consists of three yarn systems that are woven in the terry loom as can be seen in Figure 1. This terry weaving machine as seen in Figure 1, is very complex and consist of many different steps to make the product high quality (Powell & Yilmaz, 2005).

As technology becomes more advanced, the production of terry fabrics begins to increase in complexity and processing times are longer and more sensitive. To create a durable terry textile in large quantities, it is required that a weaving machine be present for assistance. The weaving machine consists of three yarn systems that are woven in the terry loom as can be seen in Figure 1. This terry weaving machine as seen in Figure 1, is very complex and consist of many different steps to make the product high quality (Powell & Yilmaz, 2005).